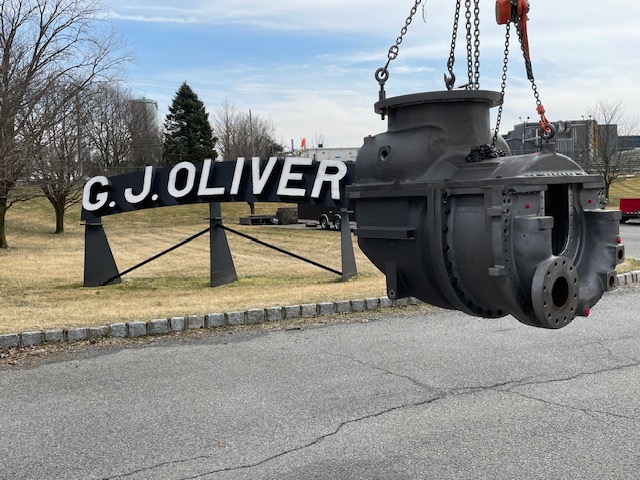

G.J. Oliver was founded on the core competency of heavy fabrication and in the early days the machine shop operation existed solely as a support function of the fabrication shop.

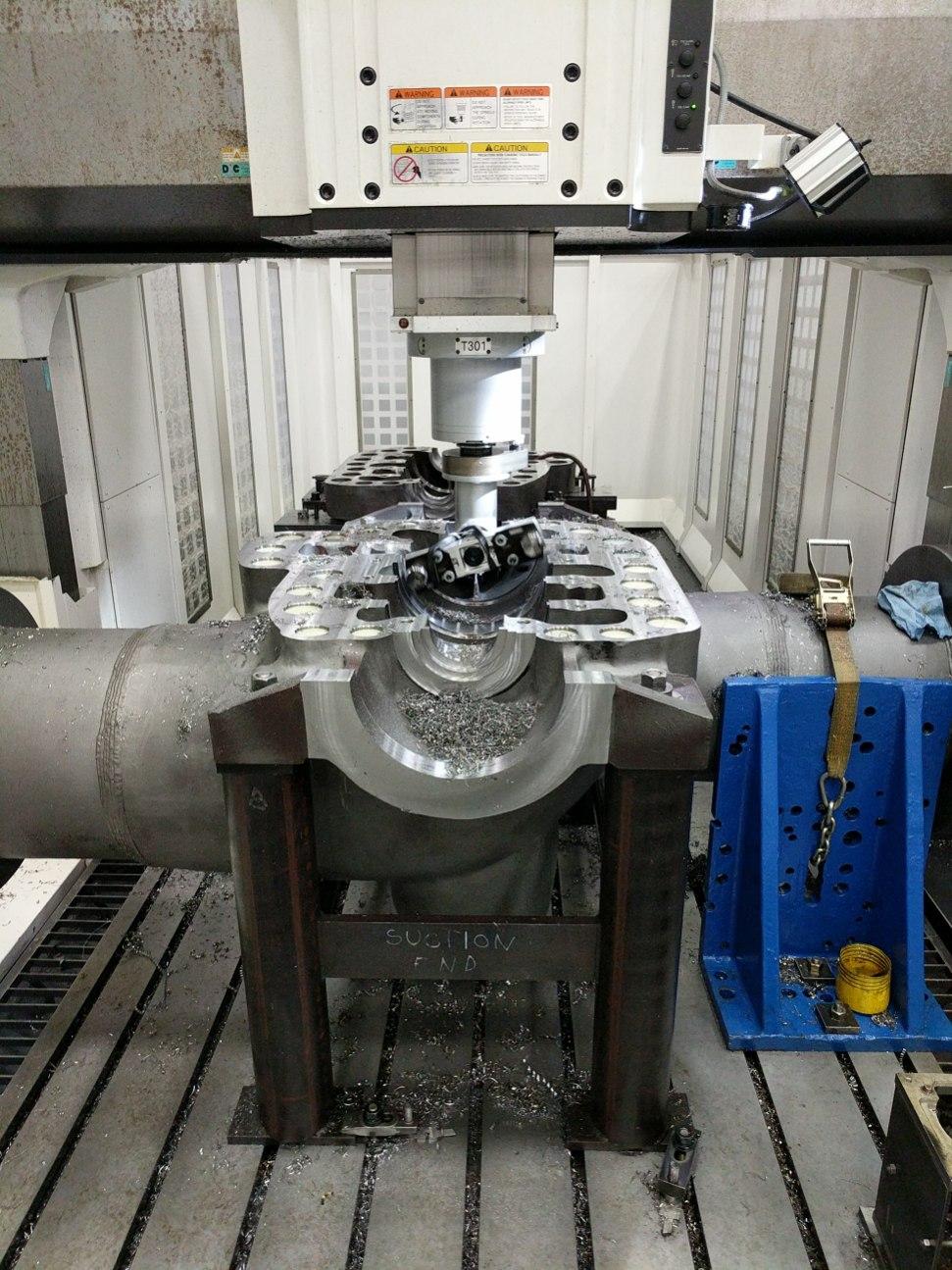

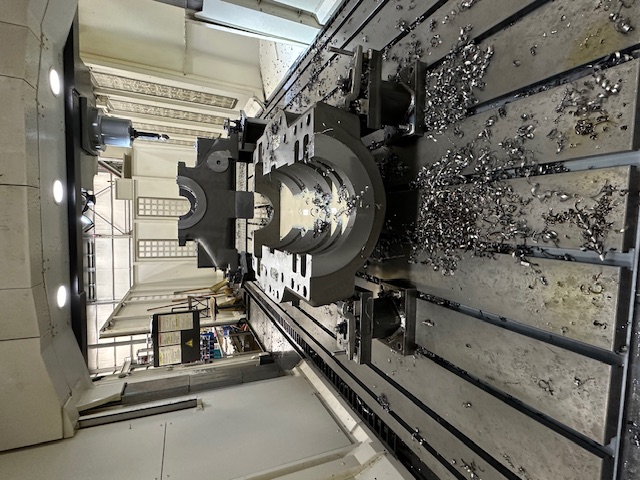

Over the past decade machining operations have progressed to become a fully functional close tolerance job shop operation with a core competency of handling large and enormous pieces. Currently our machining capabilities range from basic to complex. We maintain the art of manual machining with drilling, milling and turning and large keyway cutting but also have machine tools that utilize some of the latest technology in the industry. At G.J. Oliver we are familiar with many types of materials as well ranging from commonly used carbon steel to more difficult to work with alloys including OEM proprietary materials. We also manage process driven manufacturing of machined components with complex geometry, close tolerances and special alloys. Because of the welding capabilities and qualifications of our fabrication shop the products that require welding and or heat treat are better orchestrated being that it is all under the same in-house management. We use a the latest CNC software programming tools and 3D modeling engineering software to develop machining tool path programs for boring, turning and milling.

Our Equipment

- 1 - Vertical Boring Mill 36” Swing

- 1 - Vertical Boring Mill 48” Swing

- 1 - Vertical Boring Mill 60” Swing

- 1 - Simmons Vertical Boring Mill 144” Rotary Table

- 1 - US Burke Millright Vertical

- 1 - TOS Horiz Boring Mill w/ 5" Bar & Rotary Table

- 5 - Lathes

- 6 - Radial Drills

- 1 - Skoda W200HC Horizontal Boring Mill with 47'

- Bed and 157” Vertical Headstock Travel

- Mitts & Merrill 6S-HYD Keyseater

- Mitts & Merrill NO. 2 HYD Giant Keyseater

- 1 - Toshiba TSS-C Vertical Boring Mill with 215” Rotary Table and 102” Cutting Height.

- Morando 42/50 Vertical Turning, Boring Machine

- Shibaura Horizontal BTH-130.R24 Boring & Milling Machine

- 1 - TOS WHQ 13 CNC Horiz Boring Mill

- 1 - Toshiba TUE150S Vertical Mill (78” Table)

- 1 - Okuma Gantry Mill

- 1 - Toshiba TMD–20 Vertical Turning, Bore & Milling

- 1 - Union P150 Horizontal Boring, Drilling & Milling

Rotor / Impeller Balancing

- 1 - Schenck HM-50B

Are you ready to find out how we can help you succeed?

Click on the button to the right and fill out our contact form. We'd love to talk about your next project and how G. J. Oliver can help bring it to life.